A demand planner is a professional who analyzes market trends for various products and services to forecast future demand. While predicting the future is inherently uncertain, a well-executed demand planning process can be highly accurate.

Effective demand planners collaborate closely with the marketing department to develop long-term strategies for the business's products and services. They consider various factors, including:

Historical sales data

Market trends

Logistics

Risk assessment

Inventory levels

Customer preferences

Demand planner recommendations and forecasts are not set in stone and may not always be accurate. Therefore, the final decision on implementing plans and business models should involve stakeholders beyond the planner to avoid conflicts of interest.

A great demand planner possesses the ability to think critically, be flexible, and communicate honestly about the company's current and future prospects. They play a crucial role in shaping the business's brand by identifying and targeting the right demographics for its products and services.

A skilled planner can strategize effectively with the market, use the latest tools and techniques to collect and analyze data, and deliver recommendations that generate both immediate revenue and long-term opportunities.

What Makes a Great Demand Planner

The demand planning market is a multibillion-dollar industry with projected growth well into the future. According to the Bureau of Labor Statistics, even basic logisticians are expected to see a 19% growth rate annually, suggesting a similar trajectory for demand planners until 2034.

The key to being a great demand planner is maintaining meticulous records, by using the proper information systems and integrations. Analyzing past trends provides valuable insights into consumer preferences, forming the basis for accurate forecasts. However, historical data should serve as a guide rather than a definitive predictor of future trends. Analyzing current market conditions is crucial for enhancing planning skills and overall knowledge.

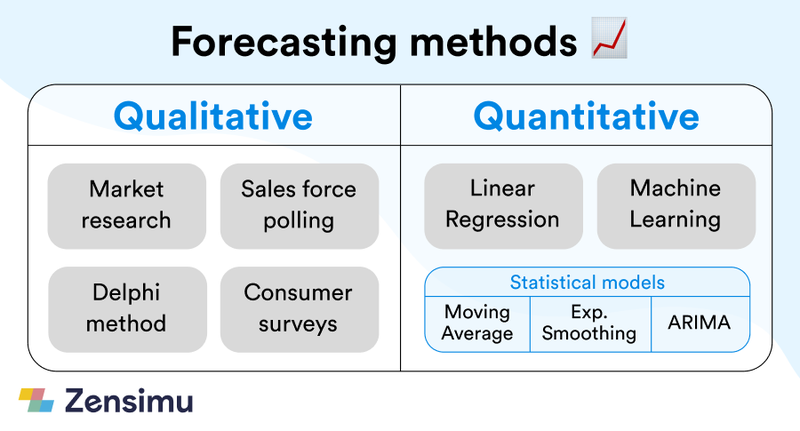

Mastering various statistical models and algorithms is essential for accurate demand forecasting. Techniques such as moving averages, exponential smoothing, and ARIMA (AutoRegressive Integrated Moving Average) models help planners analyze historical data and predict future trends. Moving averages smooth out short-term fluctuations to highlight longer-term trends, while exponential smoothing gives more weight to recent data points, making it more responsive to changes. ARIMA models combine autoregression, differencing, and moving averages to capture complex patterns in time series data. By understanding and applying these models, demand planners can significantly improve the accuracy of their forecasts.

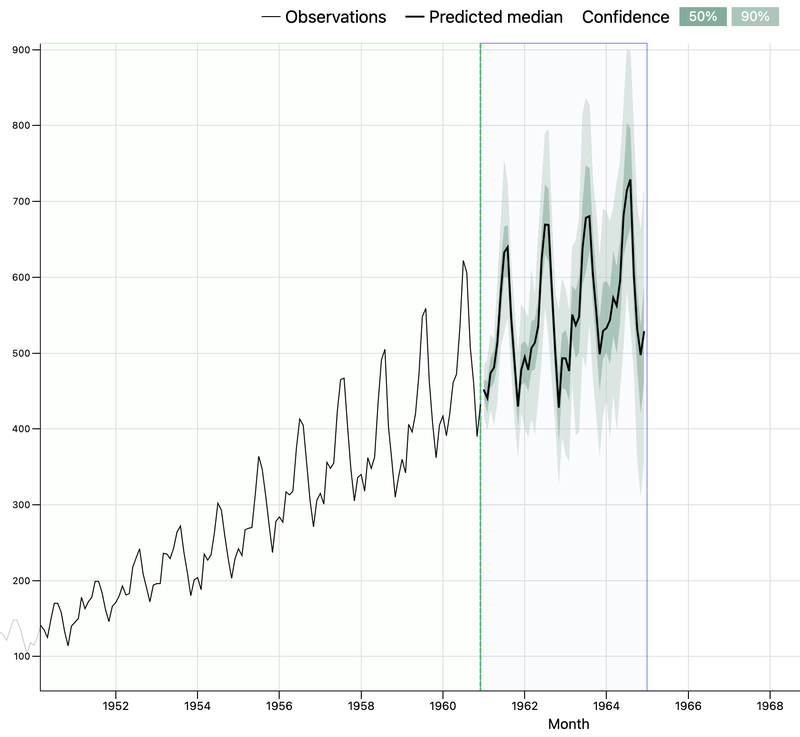

Artificial Intelligence (AI) and Machine Learning (ML) can revolutionize demand planning by automating data analysis and identifying patterns that humans might miss. AI algorithms can process vast amounts of data quickly, providing real-time insights and predictions. Machine Learning models can learn from historical data and continuously improve their accuracy over time. For example, AI can analyze market trends, pricing/promotions, stock availability and external factors like weather and economic conditions to generate more precise demand forecasts. By leveraging AI, demand planners can make data-driven decisions, optimize inventory levels, and enhance overall supply chain efficiency.

Example of ML forecast from The Forecasting Company:

Tracking key performance indicators (KPIs) is crucial for evaluating the effectiveness of demand planning strategies. Important KPIs for a demand planner are forecast accuracy (MAPE/MAE) and forecast-value-added. Other Supply Chain KPIs can also be impacted by the work of a demand planner (although other factors come into play), such as turnover ratio, or fill rate. Forecast accuracy measures how closely the predicted demand matches actual demand. Forecast value-added tracks every time a change to the prediction is made, and if these changes are actually improving the forecast accuracy. The inventory turnover ratio indicates how efficiently inventory is managed. The fill rate reflects the percentage of customer orders fulfilled on time. Regularly monitoring these KPIs helps demand planners identify areas for improvement and optimize their strategies.

A collaborative and data-driven approach is indispensable for accurate forecasting. Planners must continuously review the latest information (sometimes spread over multiple departments), adjust current strategies, and evaluate their effectiveness. For example, if a marketing campaign targeting women aged 25-35 fails, the planner should collaborate with the marketing department to analyze the data, identify issues, and make necessary adjustments. This iterative process of analysis, collaboration, and adaptation is key to success.

Case Study: How Bose engaged its teams in the forecasting process

The electronics giant inspires employees to learn lessons from worldwide supply chain shortages and better collaborate in the future.

How Can Zensimu Help You Develop the Skills of Your Demand Planning Teams?

Zensimu specializes in teaching and inspiring business professionals through interactive games. Our "gamified learning" approach is particularly effective for demand planning, with the Beer Game simulation being our flagship method.

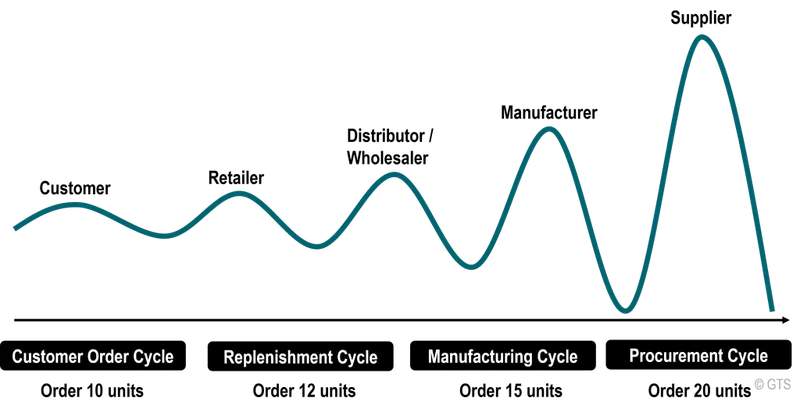

The Beer Game, originally developed at the Massachusetts Institute of Technology in the late 1960s, is a logistics problem-solving exercise. Players take on roles such as manufacturer, distributor, wholesaler, or retailer, working together to optimize the supply chain. The game emphasizes the importance of mitigating the "Bullwhip Effect," where small changes at the retail level can have significant impacts throughout the supply chain.

Our Supply Chain game allows you to create a scenario and simulate various events such as promotions, supply or production issues, that require a collaborative approach to succeed.

Taking the role of a supply chain manager / planner, trainees need to face uncertainty in the demand, by analyzing the historical needs they received from their client, and make estimates for the future.

It is also a good way to sensibilize all employees to the complexities of a multi-tiered supply chain, and how stakeholders are dependent on each-other.

Conclusion

At Zensimu, we propose more than just fun games. We put helping our clients in as many different ways as possible first, and we'd be happy to discuss all the ways we can help you with demand planning. Contact us today to find out more.

Sensibilize your Demand Planning team

Create an instructor account to discover our platform and develop customized scenarios, relevant for your business.