Are you struggling to meet customer expectations with your current production process? You have probably tried several strategies to improve your operations, but something is still missing. Well, the solution might be in takt. We will help you discover what takt is, how to calculate it, and how you can implement it in your company. Read on to find out.

What is Takt Time?

Takt is the duration a manufacturer takes to complete a product in order to meet customer demand. This tool helps manufacturers measure the period that elapses between the manufacture of one product and the beginning of the next.

The production time includes machine downtime and excludes breaks and changeovers.

Customer demand is the rate at which a customer orders a specific quantity of products. For instance, if a customer orders a product every 6 hours, a manufacturer has to complete the product in 6 hours or less.

Takt helps manufacturers ensure a continuous flow of production and minimize waste. This tool also allows manufacturers to optimize production capacity in a way that meets customers' demands.

Takt focuses on the capabilities of a manufacturer's production process and client demand. If the process cannot meet client demand, it should be improved to ensure quicker delivery and customer satisfaction.

When takt is short, the production procedure becomes more efficient leading to increased productivity and customer satisfaction.

Illustrate the Takt Time notion in a simulated Manufacturing environment!

The best method to explain the Takt Time to your employees, students on a real case study!

When was Takt invented?

Takt originated from the German phrase 'Takzeit' which means 'cycle time'. The phrase also had other meanings like 'touch', 'beat', or 'pulse'. German engineers introduced this phrase to Japan in the 1930s.

The German aviation industry used takt during manufacturing. They used takt to measure the interval between aircraft moving from one manufacturing station to the next. Takt was introduced to Japan when Mitsubishi collaborated with the German aviation industry.

Toyota then incorporated the concept into its production system. Takt continued to gain popularity globally as part of lean production. Today, Toyota uses takt as a core element of its Just-In-Time (JIT) principle.

Difference between Takt, Cycle, and Lead time

Takt time, cycle time, and lead time are terms that people often confuse for each other. However, these terms are quite different from one another. Here is how they vary.

Takt – The duration needed to complete a product to meet consumer demand.

Cycle time – The duration needed to complete one task or manufacture one product.

Lead time – The duration it takes between receiving an order from a customer and delivering the product

These components are all integral parts of lean manufacturing. Optimizing takt, cycle, and lead durations allows manufacturers to streamline production and maximize efficiency. Manufacturers can align takt with cycle time and lead time to improve customer service and streamline production.

How do you calculate Takt Time?

Takt basically measures the duration that elapses between the completion of two consecutive units in order to meet client demand. This tool defines the duration a manufacturer has to produce each product while meeting customers' needs.

Takt is calculated based on the available production duration and customer demand. Below is how to calculate takt.

Takt Time = Available Production Time ÷ Customer Demand

The available production time is the duration a manufacturer needs to run the production operation. This includes machine downtime. However, employee breaks and shift changeover are not part of the available duration.

Takt calculation example

Here is an excellent example of how takt calculation works.

Available production time

A handbag manufacturing industry runs an 8-hour shift for 5 working days. This translates to 8 hours X 60 Minutes = 480 minutes per day.

However, employees get a 30-minute lunch break and a 20-minute preparation break every day. Therefore, during this periods, the production operation pauses.

To get the available hours of production per day, we add the break and preparation minutes. 30 + 20 = 50 minutes daily. We subtract the breaks from the total available duration. 480 – 50 = 430 minutes. The actual available production period is 430 minutes daily.

Customer demand

This is the number of products a customer orders daily, weekly, or monthly. In this case, a customer orders 100 handbags every day for 5 working days.

Takt

To calculate takt, we use the available production time, 430 minutes and divide it by the customer demand, 100 handbags. 430 ÷ 100 = 4.3 minutes. This means that the company must produce 1 handbag every 4.3 minutes to meet customer demand.

If the manufacturer takes longer to complete one handbag, they won't produce enough handbags for the customer. This will, in turn, result in longer lead times and poor customer service. To avoid this, the manufacturer should optimize the production procedure to meet client demand within the set duration.

The best tool to explain Takt Time! Used by:

-

Lean Managers, Production or Operations Directors

Six Sigma Black Belts, Green Belts, Continuous Improvement Coaches

- Training Managers, Management Consultants

How is Takt Time useful in manufacturing?

Takt can be applied to several production operations to ensure continuous flow and streamline operations. Below is how takt is used in manufacturing.

Process design

At what rate does your production process work to meet customer demand? Takt allows manufacturers to design their production processes to align with customer requirements.

They can upgrade production machines to maximize productivity and meet client demand. If your current equipment fails to meet client demand, you can make modifications to improve takt.

Production scheduling

In manufacturing, takt helps in production scheduling. Since takt focuses on customer requirements, you can schedule production to align with customers' needs.

For instance, if a customer needs 150 products per day, you should design production around the number of products your customer needs. You can add more shifts to increase production.

Capacity planning

How much production capacity do you have? Can you meet demand with your current production process? Takt allows you to align your resources to client demand. Through capacity planning, you can divert your production efforts to ensuring customer satisfaction.

Why is Takt important?

Takt can be implemented in various work functions such as manufacturing, administration, construction management, etc. Here are some benefits of implementing takt in production processes.

On-time delivery

Implementing takt ensures companies deliver products to customers within the set period. The concept focuses on manufacturing products just in the right period to meet client demand. Quick production, in turn, reduces lead time and enhances customer satisfaction. Happier customers mean more profits and increased revenue.

Reduced bottlenecks

Calculating takt helps manufacturers identify where production time is wasted. This way, they can eliminate bottlenecks and optimize production procedures. The goal is to minimize takt to meet customer requirements more efficiently.

Minimal waste

Implementing takt standardizes work and ensures consistent production. There is minimal material waste when each team within the production procedure works efficiently.

Eliminating invaluable tasks also means less material and labor waste in every workstation. Managers can enforce targets to reduce the duration wasted during the production process.

Uniform workloads

Calculating takt allows firms to identify where production is stalling. This way, production managers can distribute workloads uniformly across various machines. Uniformly distributed workloads, in turn, lead to continuous flow of production and increased output.

Quality products

Improving takt goes hand in hand in enhancing product quality. To improve takt, a manufacturer modifies equipment or uses better machines. High-quality equipment means minimal errors and quality products. Minimizing takt also allows manufacturers to identify areas that result in lower product quality and make improvements.

Increased productivity

A shorter takt period results in increased productivity to meet client demand. More productivity reduces machine downtime and maximizes profits. Increased productivity also reduces inventory and minimizes the number of raw materials that deteriorate.

Improved business operations

Takt streamlines business operations. When production runs seamlessly, other business aspects also operate smoothly. For instance, quicker production leads to quicker delivery, reduced inventory, reduced waste, etc.

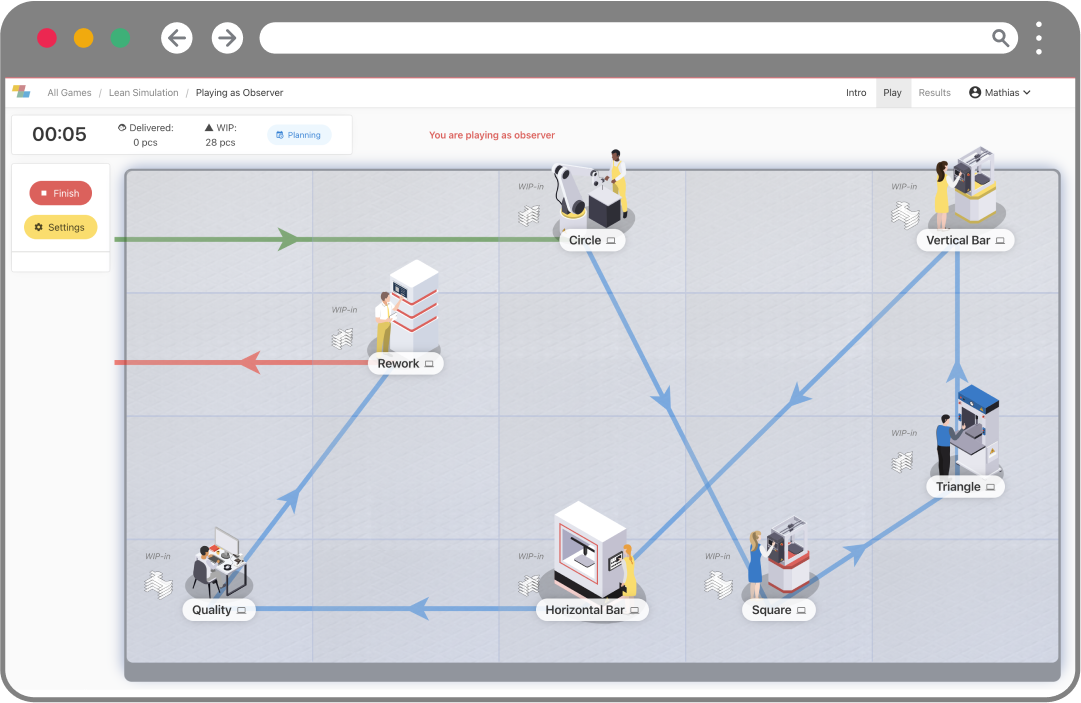

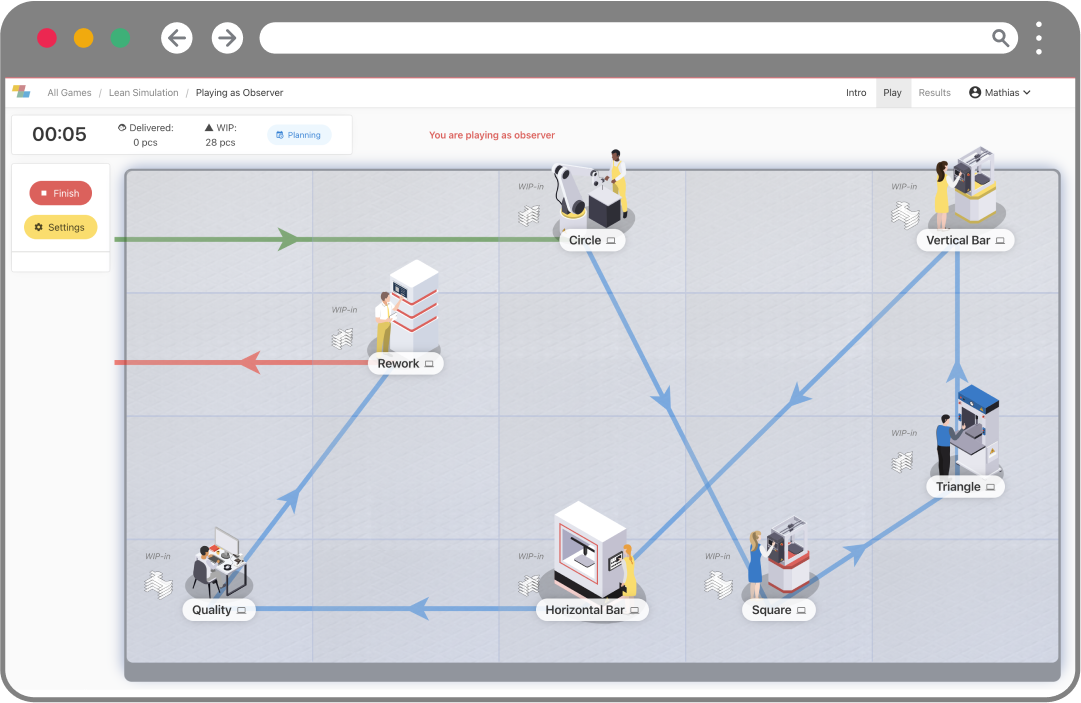

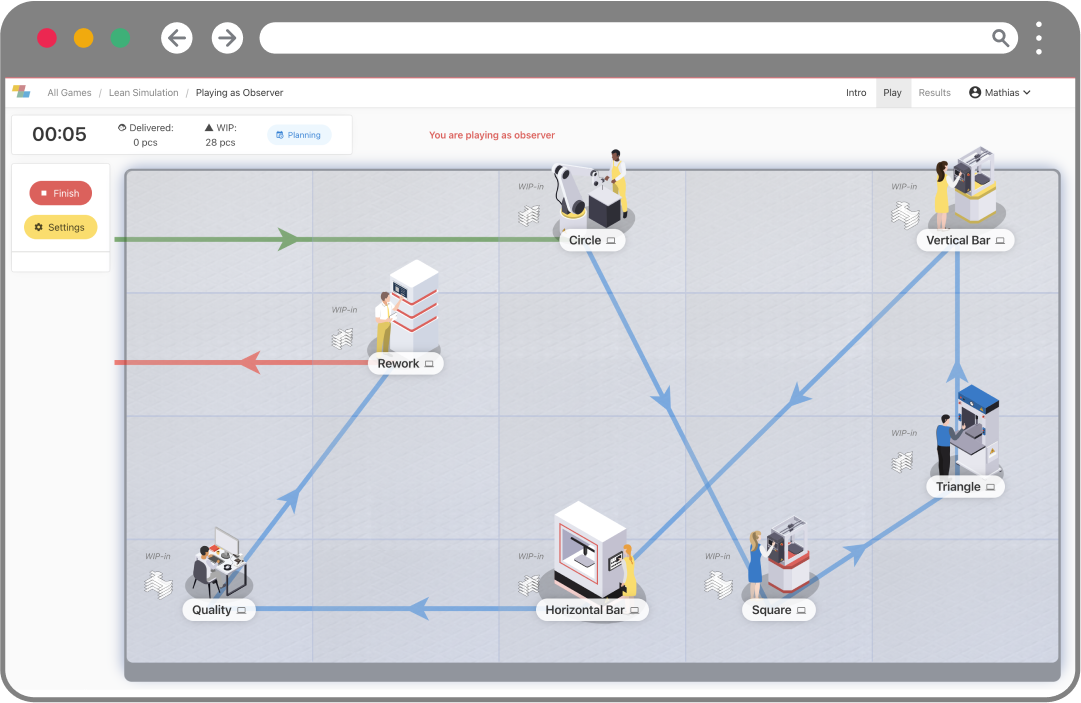

How Zensimu's Lean Game calculates Takt Time

Zensimu's Lean Game is an effective tool that professionals can use to train employees or students the concept behind takt. Using Zensimu, participants can see how implementing takt reduces inefficacies in production.

In this game, takt is calculated automatically based on the demand plan of the participant's scenario. It is up to the participant to compare takt to the cycle time in every workstation. The participants can then identify the bottlenecks slowing down production and use takt to eliminate delays.

Zensimu's Lean game provides a realistic approach to implementing takt in production operations. Production managers and teachers can use the game to teach employees and students how to implement takt to meet client demand.

A more practical approach helps employees and students understand concepts better. When they learn how takt works, they can easily implement the concept in real-life situations. Using Zensimu, employees can understand how takt helps them meet client demand and improve production procedures.

Explore Lean concepts in a simulated Manufacturing environment!

Zensimu's games have already been used by +1000 business, schools & consulting firms to illustrate Supply Chain and Lean concepts.

Takeaway

Takt is the rate at which a manufacturer produces a product consistently to meet client demand. Calculating takt involves dividing the available production duration by the client demand. Takt helps firms maximize productivity while meeting customers' needs. Minimizing takt also eliminates bottlenecks, reduces waste, and streamlines workflow. If you require additional assistance, get in touch with us today.