Are you wondering what the 5S of lean entail? You are in the right place. This article will cover what the 5S lean tool is, its principles, its benefits, how you can integrate it into work operations, and how you can use Zensimu to understand 5S better. Keep reading to discover more.

What is the 5S methodology?

The 5S methodology is a lean system that involves organizing the workplace to streamline operations, reduce waste, and increase efficiency and productivity. The lack of orderliness in an organization wastes too much time, reduces productivity, and affects customer relationships.

The 5S system promotes orderliness and creates a safer and more productive work environment. This methodology focuses on keeping the workplace clean, organized, and properly structured. When tools and materials are neatly arranged, employees can work quickly and efficiently. The 5S lean tool comprises 5 crucial steps, namely:

Sort (Seiri)

Set in order (Seiton)

Shine (Seiso)

Standardize (Seiketsu)

Sustain (Shitsuke)

The origin of 5S

The 5S lean system first came to light in Japan when Toyota incorporated it into its production procedures. As Toyota gained popularity, more companies began incorporating the 5S practice into their production systems.

Since its development, the 5S system has since gained traction in different work functions including manufacturing, healthcare, etc.

Explore the 5S Methodology in a simulated manufacturing environment!

The best method to explain 5S methodology to your employees, students, on a real case study!

What are the 5S steps?

The 5S system is a process that includes 5 pillars pioneered by the Toyota Motor Company. The 5S steps comprise Japanese words that are translated into English. These pillars include:

Sort (Seiri)

This step involves going through workplace materials and equipment to determine necessary and unnecessary items. Getting rid of unnecessary items declutters the workplace and improves its functionality.

The goal is to retain only the valuable materials needed to accomplish everyday tasks. Some points that you can consider when sorting items include:

What is the item used for?

How often is the item used?

Who uses the item?

Does it need to be at the workstation?

After identifying unnecessary items, you can red tag them, discard them, or recycle them. Red tagging involves labeling materials and equipment for future use or reassignment.

Set in order (Seiton)

After sorting items and eliminating clutter, the next step involves organizing the remaining materials. This phase focuses on arranging materials logically to make it easy for workers to locate them when needed.

Each tool or equipment should be easy to locate, use, and return. This step focuses on the principle; 'A place for everything and everything in its place.'

Items used frequently can be stored within reach and those that are rarely used can be stored farther away. Your team can use labels to easily locate materials.

Shine (Seiso)

Shine or Seiso focuses on cleanliness. After materials are organized logically, now it is time to keep dirt, grime, and dust from accumulating. This step involves the regular cleaning of the workspace, tools, and equipment.

This phase includes mopping, dusting, sweeping, regular equipment maintenance, etc. Cleaning creates a conducive working environment for team members.

Maintaining the workspace helps company teams identify faulty equipment that might affect productivity. Failure to identify problems on time results in safety hazards, machine downtime, and reduced productivity.

Standardize (Seiketsu)

This phase involves creating a systematic approach that incorporates the first 3 phases into daily workplace procedures. This pillar enforces standard management routines into place to prevent falling back into the same old habits.

Companies can standardize the 5S principles by assigning daily tasks, creating schedules, providing instructions, etc. Scoreboards, signs, checklists, and placards can help organizations set the pace for team members.

Sustain (Shitsuke)

Shitsuke or sustain means discipline. This phase focuses on sticking to the set standards and procedures. The goal is to make the 5S methodology a habit rather than a one-time affair. To sustain the 5S system, managers should actively audit processes, set measurable goals, train team members, and consistently measure performance.

How does 5S sit in the overall lean methodology?

The 5S system focuses on minimizing wastes, streamlining production operations, and maximizing productivity. The procedure creates a well-organized workspace that reduces bottlenecks and production downtime. A clean and clutter-free workplace promotes a seamless flow of business activities.

Why is 5S important for manufacturing success?

Implementing 5S has several benefits including:

Reduces waste

It can be difficult to find equipment in a cluttered and disorganized workspace. Employees waste a lot of time looking for the materials they need to complete particular tasks. This in turn derails production and affects customer service.

Implementing 5S helps companies reduce waste. When tools and materials are properly organized, companies can work quickly and effectively to fulfill customer needs. Companies can also identify defective equipment on time and reduce machine downtime.

Improves customer service

Proper workspace management also improves customer service. Time wasted looking for items can delay production and customer deliveries. Dissatisfied customers might hurt a company's reputation.

To avoid this, organizations can incorporate the 5S system into their manufacturing process. 5S minimizes delays and helps companies reach operational excellence to promote the good functioning of Lean.

Creates a safer work environment

Faulty equipment and a cluttered workspace can lead to accidents and injuries. 5S allows workers to eliminate unnecessary items that can lead to workplace hazards.

Organizing and sorting tools also allows team members to discover defective equipment that could otherwise lead to accidents and injuries.

For instance, spills can lead to slips. However, regular cleaning can minimize this risk by getting rid of spilled liquids.

Increases productivity

Production time wasted looking for materials and tools significantly affects productivity. On the other hand, when workstations are neat and organized, employees spend less time looking for crucial items leading to increased productivity. More productivity, in turn, leads to increased profits and a higher ROI.

Enhances employee commitment

Employee commitment plays a significant role when it comes to incorporating the 5S system. The team participates actively by organizing their workstations. Workers also provide useful insights when it comes to improving the working environment.

To remain effective, the 5S system requires team members to actively play their roles in maintaining a safe and sustainable environment. Employees also contribute to the management and maintenance of tools and equipment.

How do you implement 5S in practice?

Implementing 5S is a gradual procedure that requires careful analysis and consideration. Here is how you can implement 5S in practice.

Identify production issues

What operational issues are you currently facing? Can you make improvements by implementing 5S? Identifying problems in the production process allows you to figure out how integrating 5S can make operations better.

Set goals and objectives

After discovering where the problem lies, set your objectives. What do you want to achieve after implementing 5S? For instance, one of your goals might be to shorten the production process or produce more units in a day. Clearly outline your goals and the areas that need improvement.

Train the team

After setting your goals, train your team. Show them how the new process will improve the environment and increase productivity. Let the team members know what role they will play in the implementation of the new system. You can focus on a pilot area first and then deploy the system further later on.

You can also make the 5S training part of employee onboarding. Let new team members understand the 5S framework.

Integrate 5S into daily operations

Once you train your team, execute the 5S process. Incorporate the system into your team's daily operations. Come up with procedures and regulations that each team member should follow to execute the system.

Measure and improve

Is the system effective? If so, how has it streamlined operations? Measure the output against your goals. Check where the system needs more improvement. See whether the method is sustainable. Make the necessary improvements and keep measuring results periodically.

Explore Lean concepts in a simulated Manufacturing environment!

Zensimu's games have already been used by +1000 business, schools & consulting firms to illustrate Supply Chain and Lean concepts.

Where can 5S be applied?

The 5S lean tool can be useful in various types of business operations. Some of these work functions include:

Manufacturing

5S is popular in the manufacturing industry. The system is used in organizing workstations to create a conducive working environment. Toyota uses 5S as part of its lean manufacturing process to organize materials and the working space.

Healthcare

5S is used in healthcare to ensure patient safety. Proper labeling of medicine and medical tools streamlines operations and makes it easy to locate necessary tools and medical equipment.

Hospitality

No client wants to dine in a dirty and disorganized restaurant or stay in a cluttered hotel room. Most hotels, motels, and restaurants integrate 5S into their operations to maximize efficiency and provide great customer service.

Education

Students need a clean and organized environment to focus. Getting rid of clutter, creating organized storage, and cleaning classrooms create an ideal learning environment for students.

Technology

In the tech industry, labeling computer materials speeds up production and reduces delays. The materials are sorted, correctly labeled, and stored to ensure the smooth flow of production activities. Organizing data also makes it easier to retrieve crucial information.

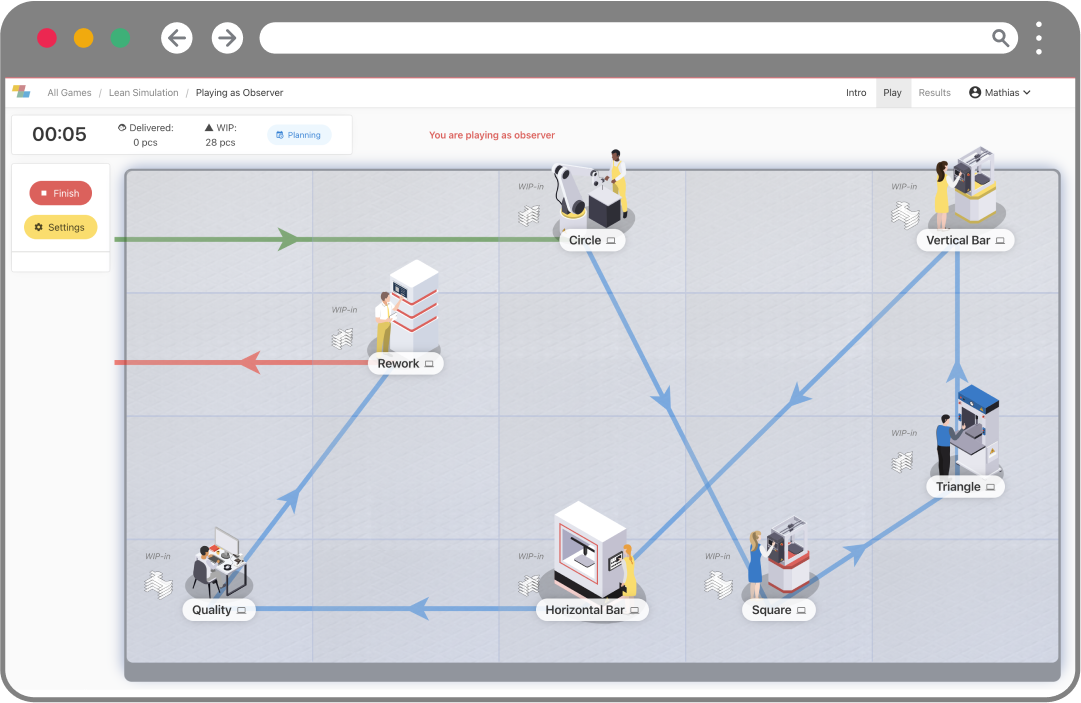

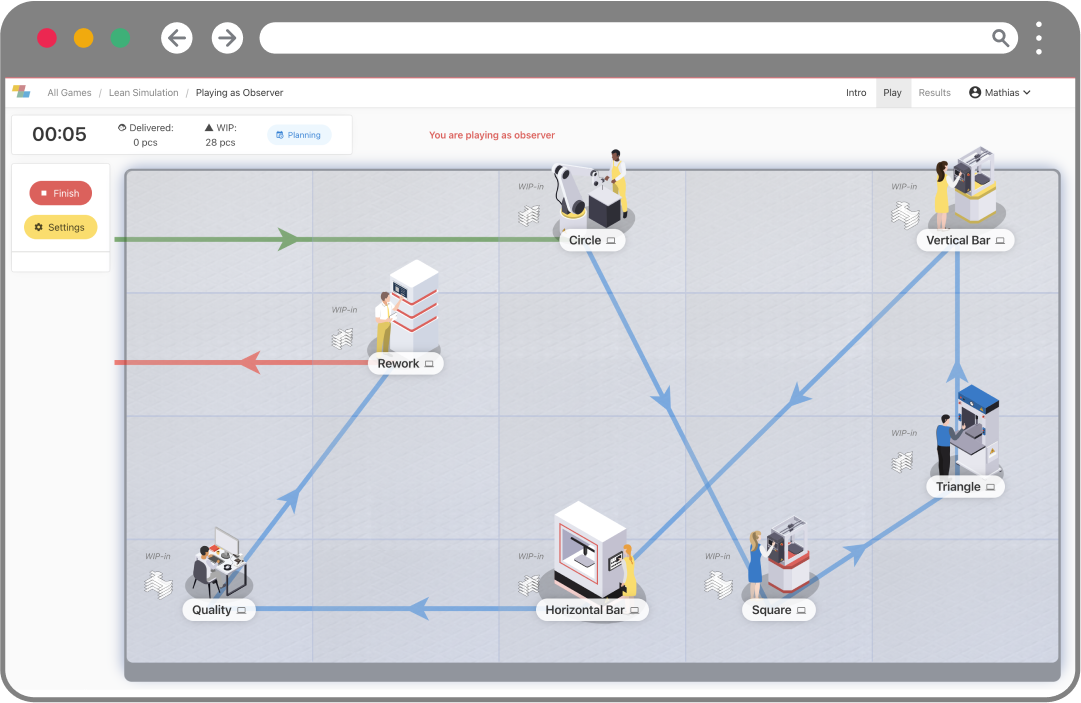

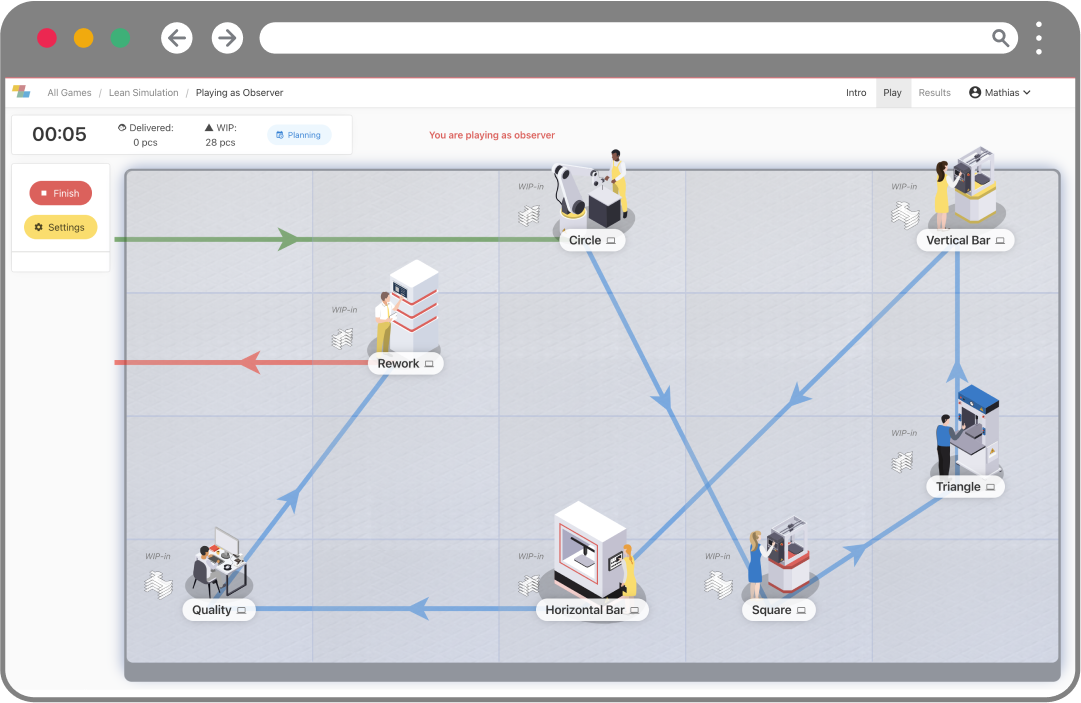

How Zensimu applies the 5S methodology

Zensimu's Lean Game allows participants to implement the 5S system in a simulated working environment. The tool allows participants to discover how 5S contributes to operational excellence. Professionals can use the game to train learners and workers on how 5S improves performance.

The participants understand how 5S contributes to lean production. Through this game, professionals can help employees see how 5S improves efficiency and promotes productivity and sustainability. Participants can understand the system better through practice.

Explore Lean concepts in a simulated Manufacturing environment!

Zensimu's games have already been used by +1000 business, schools & consulting firms to illustrate Supply Chain and Lean concepts.

Bottom line

5S is a lean tool that focuses on creating an organized workspace to streamline work operations. The system includes 5 steps that companies can follow to create an ideal working environment. 5S can be implemented in various industries including healthcare, manufacturing, hospitality, etc. If you require more information, don't hesitate to contact us today.