The aerospace supply chain plays a pivotal role in global commerce and defense, encompassing an intricate network of suppliers, manufacturers, and service providers. This vital component ensures the seamless production and maintenance of aerospace vehicles, from commercial aircraft to defense systems.

This blog post delves into the complexities of the aerospace supply chain, offering insights into its unique characteristics, evolution, current trends, and the challenges companies face within this dynamic field. Through the innovative lens of simulation tools, like our specialized aerospace supply chain simulation, we'll explore how these tools can enhance understanding, streamline operations, and foster key learnings for professionals in the sector.

What is the Aerospace Supply Chain?

The aerospace supply chain is the cornerstone of aviation and space exploration, encompassing all processes from raw material sourcing to the final assembly of aircraft and spacecraft. This elaborate system involves a myriad of stakeholders, such as OEMs (Original Equipment Manufacturers) like Boeing and Rolls Royce, tiered suppliers, logistics providers, and regulatory bodies.

They all collaborate closely to ensure every component adheres to the highest standards of quality and safety. The aerospace supply chain is instrumental in integrating thousands of individual components, sourced from a global network of suppliers, into the engineering marvels that navigate our skies and space.

However, what distinguishes the aerospace supply chain from other industrial sectors? The subsequent section will examine the unique challenges and complexities inherent to the aerospace supply chain, highlighting the rigorous regulatory compliance demands, the necessity for precision engineering, and the global scope of the industry that renders it distinctively challenging.

Why is the Aerospace Supply Chain Unique?

The aerospace supply chain sets itself apart through various factors, such as:

Stringent Regulatory Standards: The aerospace industry, including companies like Boeing and Collins Aerospace, is governed by stringent regulatory standards imposed by entities like the FAA and EASA. These regulations ensure that every aspect of the supply chain, from the Boeing supply chain to the Rolls Royce aerospace supply chain, meets strict safety and quality guidelines.

Complexity and Global Integration: The supply chain's complexity is heightened by the global integration required to assemble aerospace products. This complexity is evident in the airline supply chain and the aerospace and defense supply chain, where components must be meticulously coordinated across borders to ensure seamless assembly and operation.

Technological Innovation: The aerospace sector is at the forefront of adopting advanced materials and technologies, necessitating a supply chain adept at handling these innovations. This is particularly challenging when addressing aerospace supply chain problems such as integrating new materials or technologies into existing production lines.

Customization and Flexibility: The demand for customized aerospace solutions, especially in defense and space exploration, requires a supply chain that is both flexible and capable of meeting specific operational requirements without sacrificing efficiency.

Understanding the unique aspects of the aerospace supply chain, from the stringent regulatory standards to the demand for customization and flexibility, sets the stage for a deeper exploration of the hurdles this complexity introduces. While the innovative use of advanced materials and the global nature of the supply chain drive the industry forward, they also present a set of formidable challenges. In the following section, we'll delve into these challenges in more detail, examining how the very factors that make the aerospace supply chain distinctive also contribute to its most significant obstacles, including supply chain visibility, regulatory compliance, and the balancing act between cost pressures and technological advancement.

Challenges Companies Face in the Aerospace Supply Chain

The aerospace supply chain, characterized by its complexity and the critical nature of its operations, presents several formidable challenges to companies within this sector. These hurdles not only test the resilience and adaptability of supply chain networks but also demand constant innovation and strategic foresight from all stakeholders involved.

Supply Chain Visibility: One of the most pressing challenges is achieving end-to-end visibility within the supply chain. Given the multitude of components, suppliers, and processes involved, maintaining a clear view of every stage is daunting. This lack of visibility can lead to inefficiencies, unexpected delays, and increased vulnerabilities, particularly when it comes to identifying and mitigating potential disruptions.

Regulatory Compliance: Adhering to the stringent regulatory standards set by international aviation authorities is a constant challenge. Compliance is not optional; it's a fundamental requirement. The dynamic nature of these regulations, which can vary significantly across different regions, adds another layer of complexity, requiring companies to stay continually updated and compliant to avoid costly penalties and operational setbacks.

Cost Pressures: Despite the high value of aerospace products, the industry is not immune to cost pressures. Companies must balance the demands for cutting-edge technology and high-quality components with the need to control costs and remain competitive. This balancing act is made even more challenging by fluctuating material costs, economic uncertainties, and intense competition within the sector.

Innovation and Technological Advancement: The aerospace industry is at the forefront of technological innovation, which, while a driver of progress, also presents its own set of challenges. Staying ahead in technology adoption, from advanced manufacturing techniques to digital transformation initiatives, requires significant investment in research and development, skilled talent, and new infrastructure.

Risk Management and Resilience: In an industry where the stakes are incredibly high, managing risks and building a resilient supply chain are paramount. Aerospace companies must develop robust strategies to deal with potential risks, including supply chain disruptions, geopolitical tensions, and natural disasters, ensuring continuity of operations under all circumstances.

Environmental and Sustainability Pressures: With growing awareness and regulatory focus on environmental impact, aerospace companies are under increasing pressure to adopt sustainable practices. This includes reducing emissions, optimizing fuel efficiency, and ensuring that sustainability is integrated into the supply chain, from material sourcing to end-of-life disposal of aerospace components.

Navigating these challenges requires a strategic approach, leveraging technology, innovation, and collaboration to enhance efficiency, compliance, and resilience within the aerospace supply chain. As we explore further, we'll see how simulation templates, specifically designed for the aerospace sector, can serve as a vital tool in understanding and managing these complex challenges, providing valuable insights and practical solutions for companies looking to excel in this demanding industry.

While the challenges within the aerospace supply chain are significant and multifaceted, innovative solutions are at hand to navigate these complexities. One such solution is the use of specialized simulation templates. In the next section, we will explore how simulation templates, like the aerospace supply chain simulation, can aid in understanding and managing these challenges. These tools not only provide a practical framework for visualizing the supply chain but also offer an interactive environment to foster a deeper comprehension of the intricate aerospace supply chain dynamics.

How to face Aerospace supply challenges challenges with a business Game?

In the face of the aerospace supply chain's complexities and challenges, simulation templates emerge as a powerful tool for companies seeking to enhance their understanding and management capabilities. These simulations provide a virtual model of the aerospace supply chain, allowing professionals to engage with and analyze the impact of various factors and decisions in a controlled, risk-free environment.

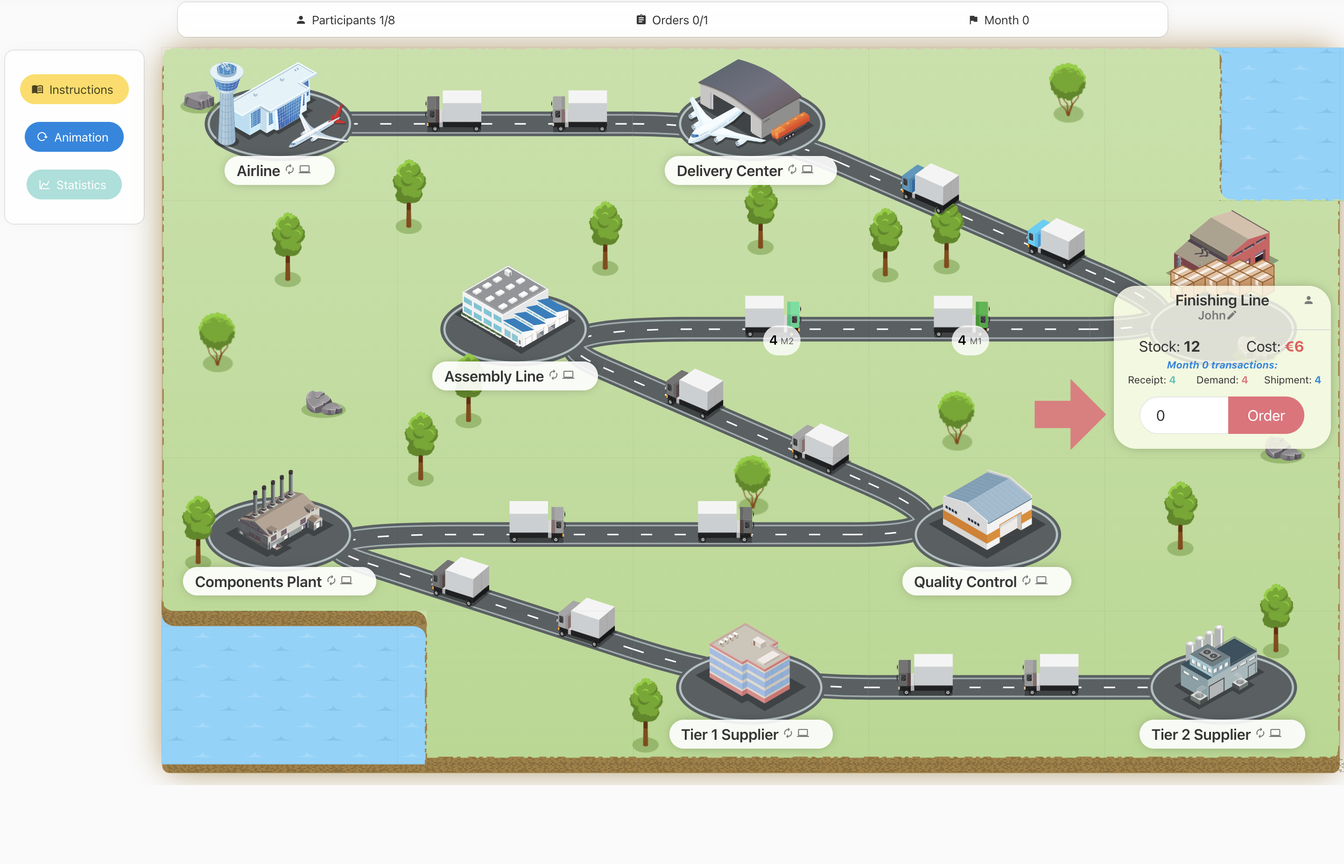

Example of our supply chain simulation: The Beer Game

Interactive Learning and Strategy Testing: Simulation templates offer an interactive platform for professionals to experiment with different supply chain strategies and scenarios. This hands-on approach to learning enables teams to see the immediate consequences of their decisions, from inventory management to supplier selection, fostering a deeper understanding of cause-and-effect relationships within the aerospace supply chain.

Visualizing Complex Processes: With the ability to model intricate supply chain networks, simulations help in visualizing the flow of materials, information, and finances across various stages and entities. This enhanced visibility aids in identifying bottlenecks, inefficiencies, and opportunities for optimization, making the supply chain more transparent and manageable.

Risk Management and Resilience Building: By simulating potential disruptions and their impacts, such as supplier failures, logistical delays, or regulatory changes, companies can better prepare for and mitigate risks. Simulation templates enable the testing of contingency plans and the development of a more resilient aerospace supply chain capable of withstanding unforeseen challenges.

Fostering Collaboration and Communication: Simulations can be used as a collaborative tool to bring together different stakeholders within the aerospace supply chain. By involving suppliers, manufacturers, and customers in the simulation process, companies can enhance communication, align expectations, and foster stronger partnerships.

Driving Innovation and Efficiency: The insights gained from simulation templates can spark innovation and drive efficiency improvements. By understanding the current limitations and future possibilities, companies can innovate processes, adopt new technologies, and implement best practices to streamline operations and reduce costs.

Incorporating simulation templates into aerospace supply chain management not only equips companies with the knowledge and skills to navigate its complexities but also empowers them to make informed, strategic decisions. As we look ahead, these simulations will continue to play a crucial role in preparing professionals for the dynamic nature of the aerospace industry, transforming challenges into opportunities for growth and advancement.

Try our ✈️ Aerospace supply chain simulation, It's free!

Get an overview of all possibilities of our Aerospace Supply chain simulation game!

In the following sections, we will delve into the specific learnings participants can gain from engaging with an aerospace supply chain simulation template and how these insights can be applied to improve real-world supply chain operations, ensuring companies are well-equipped to soar to new heights in aerospace excellence.

Key Learnings from the Aerospace Supply Chain Simulation

Engaging with our aerospace supply chain simulation offers participants invaluable insights into the complexities and strategic nuances of managing aerospace logistics. Among the myriad learnings, three core concepts stand out for their critical impact on supply chain efficiency and resilience: the Bullwhip Effect, Extended Supply Chain, and Synchronized Planning.

Understanding the Bullwhip Effect: One of the pivotal lessons from the simulation is grasping the Bullwhip Effect, a phenomenon where small fluctuations in demand at the retail level cause progressively larger fluctuations up the supply chain. This effect can lead to significant inefficiencies, such as overstocking or stockouts, and is particularly challenging in the aerospace sector due to long lead times and high-value components. Through the simulation, participants learn to identify the early signs of the Bullwhip Effect and implement strategies to mitigate its impact, such as improving demand forecasting and reducing order batch sizes.

Navigating the Extended Supply Chain: The aerospace industry's supply chain is notably vast and multi-tiered, extending from raw material suppliers to final assembly and beyond, into aftermarket services. The simulation highlights the importance of managing this extended supply chain effectively, ensuring that each link in the chain is aligned and optimized. Participants gain insights into the complexities of coordinating with a wide array of suppliers, the importance of maintaining quality across all tiers, and the need for transparency and traceability throughout the supply chain.

Mastering Synchronized Planning: Synchronized Planning, or the alignment of supply chain activities to ensure harmonious operation, is another critical area of learning. The aerospace supply chain demands precise coordination of production schedules, delivery timelines, and maintenance operations. The simulation provides practical experience in developing integrated planning processes, leveraging tools like ERP (Enterprise Resource Planning) systems, and fostering collaboration among all stakeholders. This synchronized approach helps in minimizing delays, reducing inventory costs, and enhancing overall supply chain performance.

Basic supply chain concepts

Stock, lead time, costs, orders, demand, etc.

The Bullwhip Effect

Erratic demand variations, which increase up the chain

Impact of various supply parameters

Visibility, batches, price fluctuations, etc.

Effects of human behavior

How collaboration — or lack of — can impact overall performance

Through the aerospace supply chain simulation, participants not only come to understand these key concepts but also learn to apply them in a way that mirrors real-world scenarios. This hands-on experience equips them with the skills and knowledge necessary to address the unique challenges of the aerospace supply chain, driving improvements in their organizations and contributing to the industry's advancement.

Use Cases for ou Aerospace Supply Chain Simulation

Supply chain simulations are practical resources that can be utilized in various scenarios to enhance decision-making, strategic planning, and operational efficiency. Here are some key use cases for when to implement these simulations:

Strategic Planning Sessions: During annual or quarterly strategic planning meetings, simulations can help leadership teams visualize the impact of different strategies on the supply chain. This can guide more informed decision-making and help in setting realistic, achievable goals.

Training and Onboarding New Employees: For new team members, simulations offer a hands-on way to understand the complexities of the aerospace supply chain. They can accelerate the learning curve, making the onboarding process more effective and engaging.

Team Building and Collaboration Exercises: Simulations can serve as team-building activities, promoting collaboration and communication among different departments. By working together in a simulated environment, teams can break down silos and improve cross-functional cooperation.

Risk Management and Contingency Planning: In times of uncertainty or when preparing for potential disruptions, simulations can help companies test their contingency plans and risk management strategies. This ensures that when real-world challenges arise, teams are better prepared to respond effectively.

Innovation Workshops: When exploring new technologies, processes, or supply chain models, simulations provide a risk-free environment to test and iterate on innovative ideas. This can foster a culture of creativity and continuous improvement within the organization.

Supplier and Partner Integration: To enhance collaboration with suppliers and partners, simulations can be used to align expectations and understand the impact of supply chain decisions on all stakeholders. This can lead to more integrated and efficient supply chain operations.

By leveraging aerospace supply chain simulations in these scenarios, companies can gain valuable insights, enhance team dynamics, and improve overall supply chain performance. Whether for strategic planning, employee development, or innovation, simulations offer a versatile tool to address the unique challenges of the aerospace industry.