Lean Game

Teach Lean principles with our visual multiplayer factory simulation

Engage participants through an immersive competitive game, teaching them how to apply Lean Six Sigma techniques and see their impact on the bottom line.

Larger team or looking for support? Book an introductory call →

They successfully modernize their trainings with us:

Rated 4.7/5 by our customers since 2021.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Introduce and reinforce collaborative methods, such as Lean Six Sigma, for reducing waste and achieving operational excellence.

The Object of the Lean Game

The aim of the game is for players to complete individual tasks within a factory to produce units.

The overall team has to deliver finished goods to customers on time.

The teams play several rounds, adding incremental improvements to reduce waste and improve operations.

→ Play to learn key insights into lean processes, such as:

Spaghetti diagrams

Just-in-time and Kanban

Reducing batch sizes

Balancing Workload

Self-inspection (Jidoka)

Reducing change-over (SMED)

Demand levelling (Heijunka)

Mistake-proofing (Poka-Yoke)

What is the impact of Lean Game?

Learning retention

Our platform’s simulation games significantly increase trainee engagement, instilling lessons learned from the start.

Training speed

Employees using our digital solutions complete their training faster, with less setup and data-collection time.

Training costs

Companies greatly reduce costs when hosting virtual learning sessions with our platform.

Performance

Employees report substantial improvement in job performance after participating in game-based training sessions.

1

Step 1

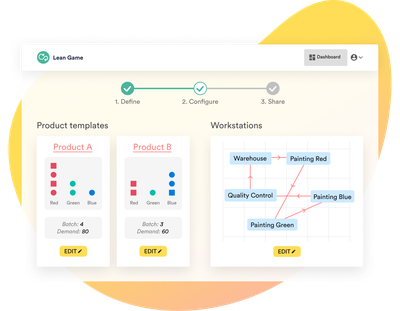

Setting Up a Game

Instructors have an extensive set of features and options for creating a custom Lean Game.

Customize game layout, products and customer demand.

Set multiple rounds with incremental improvements to impact performance.

Adapt and adjust scenarios depending on number of players or allow the Computer to play unfulfilled roles.

2

Step 2

Hosting and Gameplay

Once set up, invite participants into the “factory” and let the games begin!

Provide in-game onboarding to prepare players for each role.

Players play each role using the mouse and under time pressure.

Allow players to experience and discover production challenges on their own.

3

Step 3

Debriefing and Discussion

Even when the game is over, the learning is just beginning! Review automatically generated post-game analysis and statistics.

Check out data from various angles and formats, such as bar graphs, PDF, etc.

Compare the performances of different stations, teams and rounds.

Introduce key lean concepts, such as Takt Time, SMED, Kanban, Just-in-Time, etc.

Exclusively designed for you

Operational Leadership and Management

Lean Managers, Production Directors, Operations Directors

Quality and Continuous Improvement Specialists

Six Sigma Black Belts, Green Belts Continuous Improvement Coaches

Training and Consultation

Corporate Trainers, Training Managers, Management Consultants

Operational Excellence

Operational Excellence and Business Transformation Managers, OPEX Leads

FAQ - All you need to know about the Lean Game!

The Lean Game is a learning simulation that represents a workshop painting wooden toys. It illustrates the risks and sources of waste in a production environment.

By using Lean principles/tools, players experience a more efficient process and see the improvement of several KPI performances.

Yes. With a free account, you can create solo sessions, allowing you to explore the application by playing against the computer.

To organize sessions with external participants, a paid plan is required. This helps us offer pricing that matches the value received while building a sustainable business.

Physical Lean games can be a good solution if you already have the necessary equipment/educational content and for small in-person groups.

However, Zensimu’s Lean Game offers several advantages:

It can be played remotely, allowing participants from different locations to join and connect.

A session can accommodate a larger number of participants.

Setup is generally faster and easier than with physical games.

Additionally, the digital format offers enhanced tracking and data analysis capabilities to highlight key dynamics.

The Lean Game is designed for professors, corporate trainers, consultants, and operational excellence managers seeking to improve understanding of Lean Six Sigma objectives/benefits.

It is particularly beneficial when implementing or reinforcing internal Lean programs.

Le Lean Game aide à explorer plusieurs concepts, tels que les 7 gaspillages, ainsi que divers outils/améliorations :

Layout de l’atelier / Diagramme spaghetti,

Takt time et équilibrage des charges,

One-piece-flow et réduction des tailles de lots,

Jidoka / Auto-inspection du travail,

Demande nivelée / Heijunka,

Kanban,

Réduction des temps de changement / SMED,

Poka-Yoke

It’s unlimited! You can also add multiple organizers, which is essential for managing large groups during sessions, facilitating learning, and debriefing, or for those who are not comfortable organizing a session alone.

Yes, of course. You just need to schedule a demo with us or sign up directly!

You can create an unlimited number of game sessions. However, for conference plans, we limit the number of participants who can join your games during the plan’s duration.

If you’d like to try a premium plan before deciding, a trial period can be activated on an individual basis. To request this, please contact us at [email protected].

You can pay with a credit card for all plans. For annual plans or conference plans exceeding €500, we can issue an invoice payable by your company or university via bank transfer. If needed, you can generate a quote here, then contact us at [email protected].

Yes. We hope that educators and professionals will use the application repeatedly throughout the year—in classes, workshops, training sessions, seminars, etc.

We recommend annual plans to fully explore Zensimu’s range of features. However, if you only need the application for a one-time event, we offer conference plans.