Lean Transformation: Noddy and His Dog Game Template Page

Learn how to streamline production and achieve Manufacturing Excellence with eight Lean Transformation tools.

What is the LT Noddy and His Dog Game?

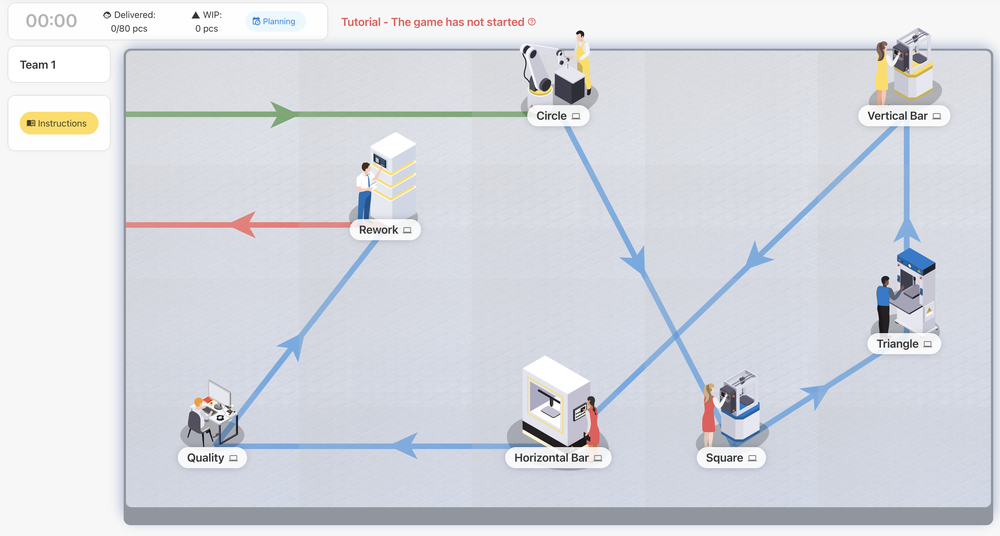

Zensimu’s Lean Transformation Noddy and His Dog Game is an interactive, educational simulation designed to train players on how to integrate Lean processes into a toy production line. It offers users hands-on experience on how to identify inefficiencies in the production process and respond by the strategic selection of Lean Improvement concepts and tools in real-time.

Who is it for?

Our LT Noddy and His Dog Game is a great way to take the skills development of operational teams and trainees to the next level. Players can learn step-by-step proven Lean manufacturing best practices deployed by the major international production lines.

When to use the LT Noddy and His Dog Game template

The simulation should be used in training sessions, educational courses, and strategy workshops to enhance understanding of Lean Excellence. It's particularly beneficial for:

New employee onboarding to introduce them to Lean Sigma Six concepts

Team development exercises to foster better collaboration and decision-making

Academic settings to complement theoretical knowledge with practical experience

How to use the LT Noddy and His Dog Game template

Over the course of several rounds, instructors can break down what makes a production process truly Lean and provide players with the practical opportunity to apply what they learn along the way. Between rounds and in the post-game debriefing, there are numerous data points to analyze in their quest to create the highest-quality products in the most cost-effective process.

Key Learnings

The simulation offers deep insights into essential Lean concepts of manufacturing excellence, including:

Workshop Layout: Understanding how to position work stations to facilitate the uninterrupted flow of products with maximum efficiency and quality

Batch Size Reduction: How to reduce WIP, increase reactivity, improve service quality, etc., from adjusting batch sizes moved between stations

Auto-Inspection (Jidoka): The benefits of detecting anomalies in real-time as opposed to correcting all defects at the end of the production line

Workload Balance: How to ensure station time is equal or below Takt Time, the minimum pace for delivering products to fulfill customer orders

Level production plan (Heijunka): How starting production early and mixing product types can reduce WIP and increase overall reactivity of the production process

Error Prevention (Poka Yoke): Reducing rework, scrapping, and overprocessing by adding click-guides in the game’s paint zones

Pull-System (Kanban): How to ensure that new product creation only starts when previous batch of products is delivered

Reduce Changeover Time (SMED): Distribute work among stations more efficiently by introducing methods and standardization in advance