What is the Multi-Clients and Bill of Materials (BOM) Game?

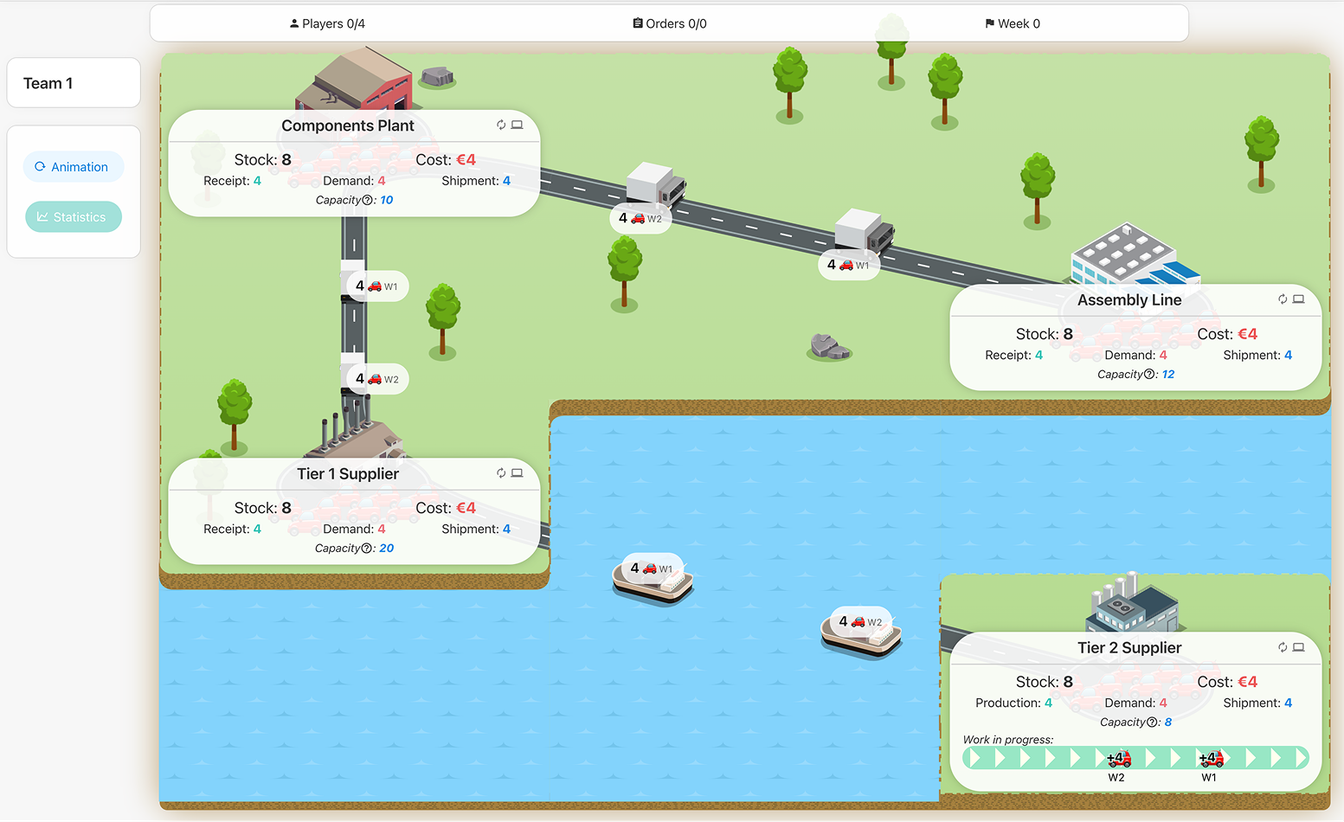

Zensimu’s Multi-Clients and Bill of Materials (BOM) Game is an interactive, educational simulation designed to train players on how to juggle demands from multiple clients as well as supply manufacturers with different items needed to assemble a product. It offers users hands-on experience in navigating the intricate logistics and decision-making processes involved in the delivery of components from suppliers to manufacturers and market-ready products to retailers.

Who is it for?

Our Multi-Clients and BOM Game is a great way to take the skills development of supply chain management trainees to the next level. Players can simultaneously practice meeting demands from multiple customers, but also learn how to order parts from different suppliers in order to manufacture a market-ready product.

When to use the Multi-Clients and Bill of Materials (BOM) Game template

The simulation should be used in training sessions, educational courses, and strategy workshops to enhance understanding of supply chain management. It's particularly beneficial for:

New employee onboarding to introduce them to supply chain management best practices

Team development exercises to foster better collaboration and decision-making

Academic settings to complement theoretical knowledge with practical experience

How to use the Multi-Clients and Bill of Materials (BOM) Game template

Instructors have an extensive set of features and options for creating a custom simulation for demonstrating the challenges and strategies of sending and receiving parts and products throughout the supply chain. Players experience a more intensive exercise in Material Requirements Planning (MRP) by introducing Bill of Materials (BOM) concepts — on top of meeting varying demands of different customers.

Key Learnings

The simulation offers deep insights into critical aspects of supply chain management, including:

Bill of Materials (BOM): Leveraging lists of items and parts needed to efficiently and cost-effectively create and deliver a final product

Forecasting: Predicting future customer demand using historical data, market trends, and analytical techniques

Safety stocks: Learning the benefits and risks of keeping extra inventory on hand to protect against supply chain uncertainties

Visibility: Tracking real-time or near-real-time information about products, inventory, orders, shipments, and processes across the entire supply chain

MOQs: Ensuring teach order is economically viable, covering costs such as production setup, handling, and transportation

Frozen periods: Seeing how no changes in orders, quantities, or schedules can maintain stability and prevent disruptions

Play our Multi-Clients and Bill of Materials Game today!