What is the Electric Vehicle (EV) Supply Chain Simulation?

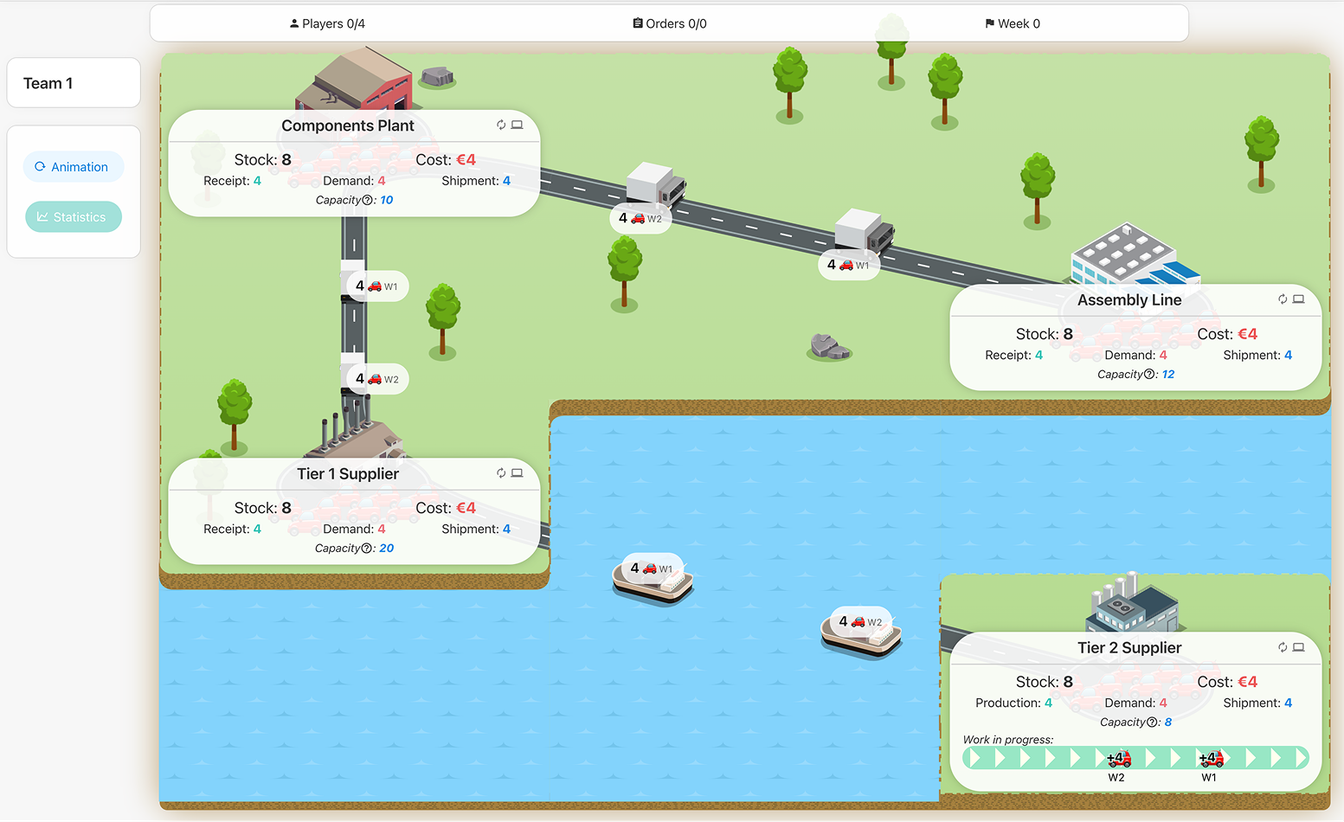

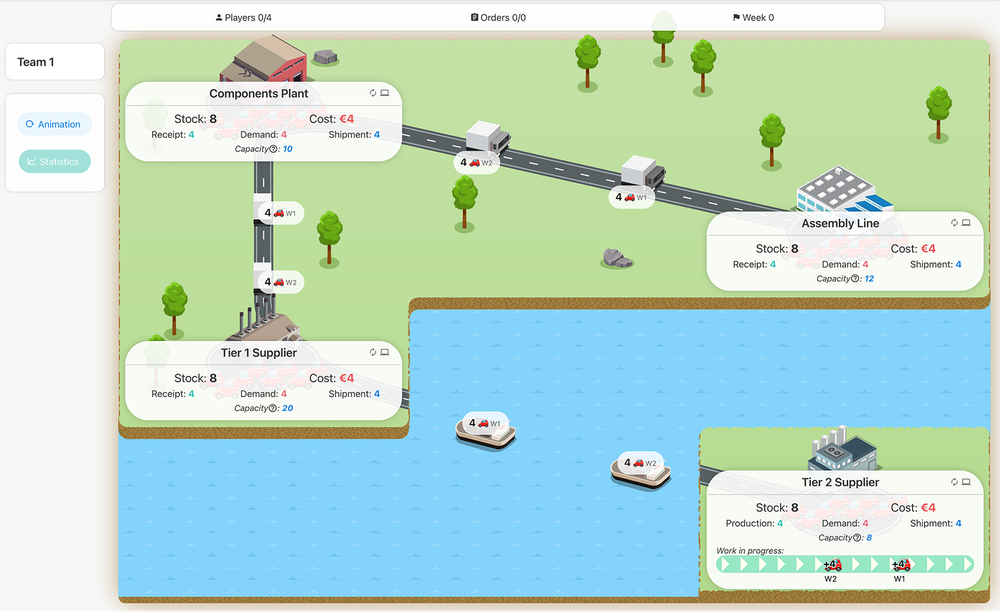

The EV Supply Chain Simulation is an interactive, educational tool designed to mimic the complexities and challenges of managing the EV supply chain. It offers users hands-on experience in navigating the intricate logistics and decision-making processes involved in the delivery of components from manufacturers to assembly lines, and onward to suppliers.

Players complete three rounds, each increasing in difficulty:

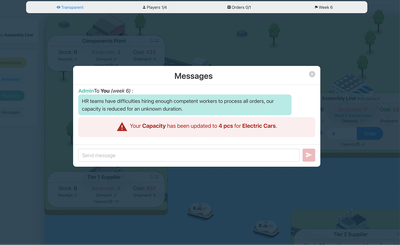

Round 1 provides fixed capacity constraints

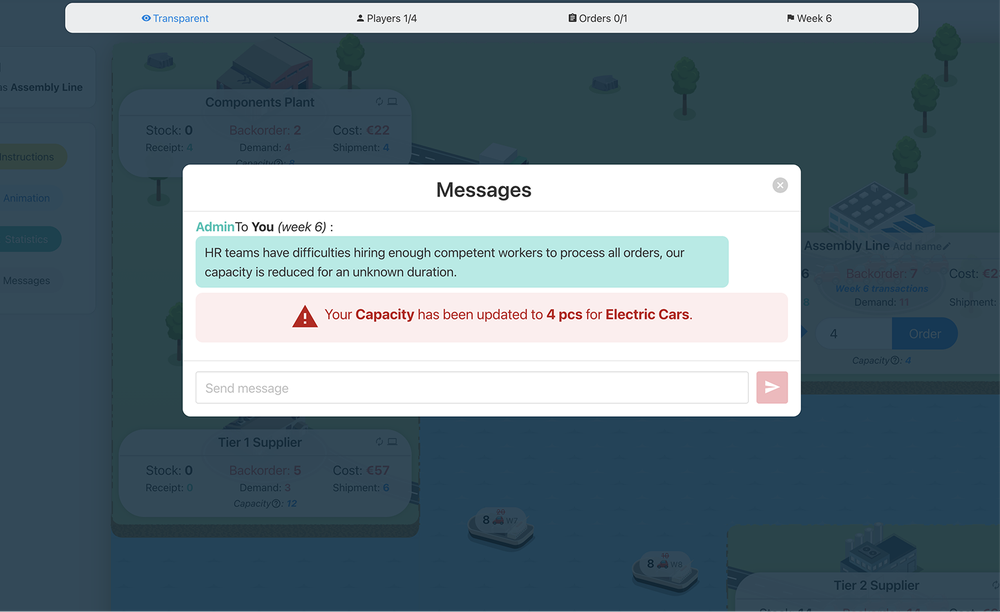

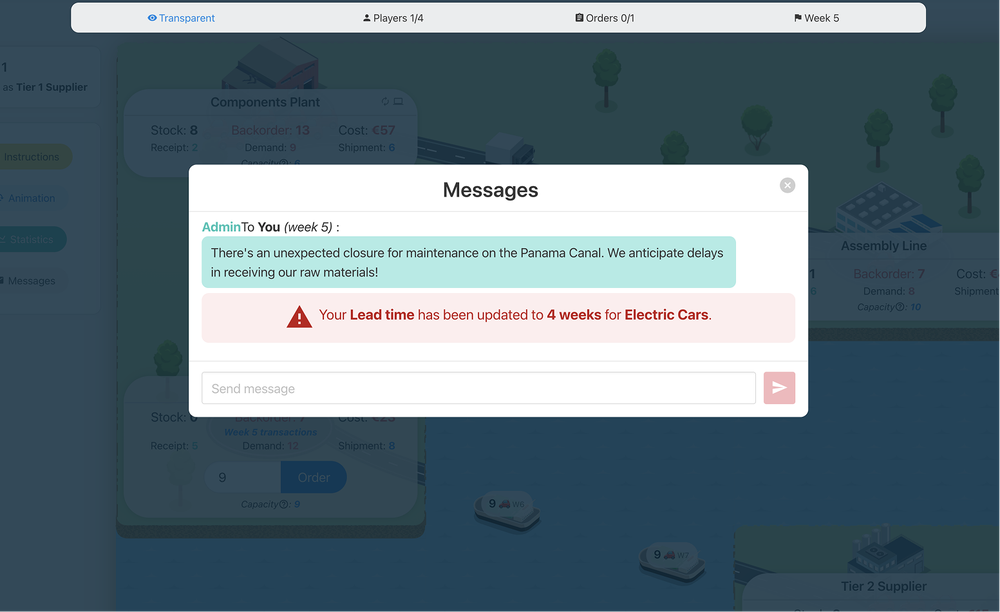

Round 2 introduces unexpected events negatively impacting capacity

Round 3 throws multiple constraints at participants, requiring optimal coordination

Who is it for?

This simulation is ideal for professionals and students in the EV industry, including mining/refining firms, battery material and cell manufacturers, powertrain and electronics suppliers, vehicle OEMs, logistics partners, etc.

It provides valuable insights for anyone studying or working along the supply chain, from procurement to distribution.

When to use the EV Supply Chain template?

The simulation should be used in training sessions, educational courses, and strategy workshops to enhance understanding of supply chain management. It's particularly beneficial for:

New employee onboarding to introduce them to supply chain management best practices

Team development exercises to foster better collaboration and decision-making

Academic settings to complement theoretical knowledge with practical experience

How to use the EV template?

Participants engage with the simulation by assuming roles within the EV supply chain, making decisions on procurement, inventory management, distribution, and crisis response. The simulation provides real-time feedback, allowing users to see the consequences of their actions and adjust strategies accordingly.

Key Learnings

The simulation offers deep insights into critical aspects of supply chain management, including:

Bullwhip Effect: Understanding how demand fluctuations impact the entire supply chain, leading to inefficiencies

Capacity Constraints: How limitations on the amount of goods or services within the supply chain supply chain leads to delays, backlogs, and higher costs.

Disruptions: How unexpected events or conditions interrupt the normal flow of goods across the supply chain, affecting a company's ability to meet customer demand

Collaboration: The importance of coordination among all supply chain participants, from suppliers to healthcare providers

Resilience: How to withstand, adapt to, and recover quickly from disruptions while continuing to operate as effectively as possible

Try our EV Supply Chain Simulation today!