We have all seen "Lean fatigue" in a classroom, where theory and slide decks fail to bridge the gap to real-world application. The right simulation is the difference between a bored audience and a breakthrough "Aha!" moment. To help you skip the trial and error, we’ve analyzed the top Lean simulations, weighing their scalability and impact so you can choose the best tool for your specific training needs.

What is a Lean Simulation Game?

A Lean Game is a "serious game" or learning simulation designed to teach the principles of Lean Manufacturing and Continuous Improvement.

The simulation typically mimics a factory environment (like an assembly line) or an office workflow. Participants are assigned specific roles—such as operators, quality inspectors, or logistics managers—and must work together in real-time to fulfill customer orders.

Typical structure

The most powerful aspect of a Lean Game is its iterative structure. Almost all versions follow a "multi-round" format:

Round 1 (Current State): Players usually start with a "Push" system. The layout is often inefficient, communication is siloed, and instructions are unclear. This round is intentionally designed to be chaotic, resulting in high stress, low quality, and unhappy customers.

Debrief & Kaizen: Between rounds, the instructor leads a debrief. Players use Lean tools to identify "Muda" (waste) and brainstorm improvements.

Round 2, 3 and more (Future States): Players implement changes like Kanban, One-Piece Flow, or SMED. They see the immediate, measurable impact of their decisions on the factory's performance.

KPIs and Learnings

To make learnings stick, Lean simulations track specific Key Performance Indicators (KPIs) that mirror real-world operations:

Lead Time: The total time it takes for a product to go from order to delivery.

WIP (Work in Progress): The amount of semi-finished inventory "piling up" between stations.

Quality Rate: The percentage of products that pass inspection without defects.

Takt Time: How well the production speed matches the rate of customer demand.

By the end of a session, participants don't just understand Lean theory, they’ve experienced its benefits. The goal is to maximize customer value by identifying the 8 wastes, balancing workloads, and creating a culture of continuous improvement (Kaizen).

Zensimu’s Lean Game

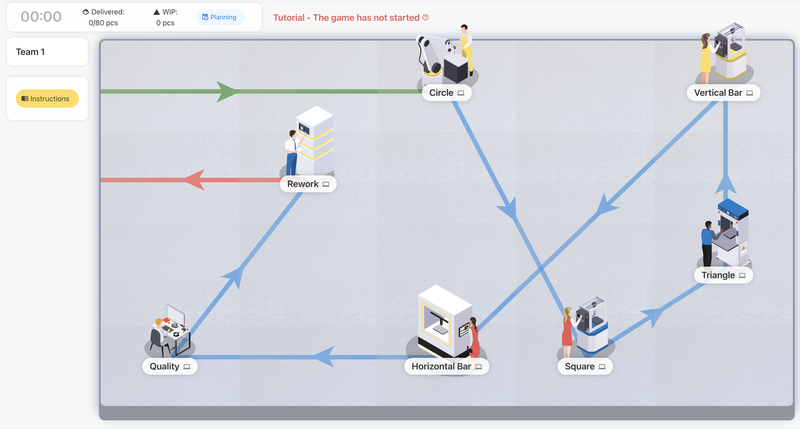

Zensimu’s Lean Game is a high-energy, browser-based factory simulation designed to bridge the gap between Lean theory and real-world application. Zensimu uses a real-time, multiplayer interface where participants manage a virtual toy-painting factory.

Players take on specific roles, such as assembly, quality control, or logistics, and must collaborate under pressure to fulfill customer orders. The simulation is built to be played in iterative rounds, allowing teams to experience the inefficiency of a traditional push system before implementing Lean tools like Kanban and One-Piece Flow to transform their results.

Features

Live Instructor Dashboard: Instructors can launch games in seconds, monitor every team and stations in real-time.

Automated Debriefing: No need to manually measure cycle times. The platform automatically generates professional debriefing charts, including Takt Time vs. Cycle Time, WIP levels, Lead Time, and P&L statements.

Customizable Scenarios: Start from one of the templates and adjust them to your own learning goals. Adjust the duration of each round, demand patterns, or lean tools available to the players.

Comparative Analytics: When a game is finished, easily compare teams and zoom on the ones where the most interesting dynamics took place. When running iterative simulations, participants can see how their score improved with different processes or parameters.

Scalability: The platform is built for modern training needs, supporting everything from a small team of 4 to large-scale university cohorts of 600+ simultaneous players across different locations.

Immersive: The game is designed to maintain the engagement level of a physical setting, through lively visuals, animated WIP and transportation flows.

Advantages

Zero Setup & Cleanup: Unlike physical simulations (like Lego or Paper Planes), there are no kits to buy, no pieces to lose, and "resetting" the factory for Round 2 happens with a single click.

Data-Driven Debriefing: Because every action is tracked, the debriefing is based on actual player data. This allows instructors to prove the ROI of Lean improvements with indisputable KPIs.

Remote & Hybrid Ready: As a cloud-based SaaS, it works perfectly over Zoom, Teams, or in a physical classroom, making it the go-to choice for decentralized global companies.

High Engagement: The real-time nature of the game creates a realistic sense of urgency. When a bottleneck occurs at one station, the entire team sees the inventory "piling up" visually, which drives immediate engagement.

Disadvantages

Digital vs. Tactile: While the simulation is highly immersive, it cannot fully replicate the tactile "clutter" of a real shop floor or the physical fatigue of moving heavy parts.

Screen Fatigue: In a very long workshop (e.g., 4+ hours), participants may experience more fatigue than they would with a physical activity that gets them moving around the room.

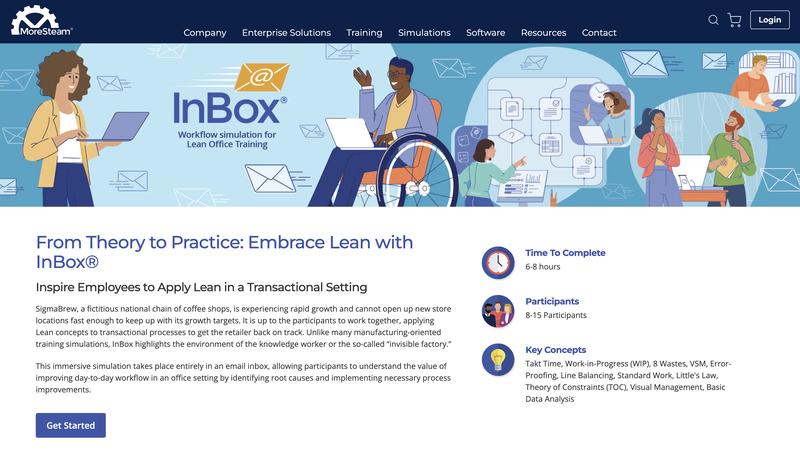

MoreStream’s Inbox

MoreSteam offers a suite of Lean and Six Sigma simulations designed to bridge the gap between theoretical training and real-world application. Their flagship offering, the InBox simulation, is specifically tailored for Lean office training. It simulates a service-oriented business (SigmaBrew) where participants manage an email inbox. Unlike manufacturing games that use physical parts, InBox uses digital "work items" (emails) to teach Lean in a knowledge-worker context. Over 6-8 hours, players identify waste, map value streams, and redesign their workflow to improve cycle time and quality.

Advantages

Focus on Service/Office Environments: Most Lean games (like the classic "LEGO" or "Plug" simulations) are manufacturing-centric. InBox is widely considered a leader for "Lean Office" training because it replicates the actual daily tools (email/spreadsheets) used by white-collar workers.

High Fidelity & Data Richness: While many competitors offer simplified "point-and-click" games, simulations like Inbox provide deep datasets and complex scenarios. This makes them better suited for Green Belt and Black Belt level training where statistical analysis is required.

Scalability & Remote-Friendly: Because they are web-based and mobile-friendly, they eliminate the need for shipping physical kits (like LEGO sets or factory models), making them ideal for global, hybrid, or remote teams.

Integration with Software: Games often integrate directly with their proprietary data analysis tool, EngineRoom, allowing students to move seamlessly from simulation to statistical modeling.

Disadvantages

Higher Cost: Positioned as an enterprise-grade solution. Individual simulation tokens or facilitated sessions (often $500-$1,000+) are significantly more expensive than other digital or physical Lean game alternatives.

Steeper Learning Curve: Because the simulations (especially Inbox/St.Sigma) are high-fidelity and detail-oriented, they can be overwhelming for "White Belt" or "Yellow Belt" beginners who might benefit more from a simpler interactive game.

Lack of Physical Engagement: Some practitioners argue that physical simulations (moving actual parts on a table) are more effective for kinesthetic learners and for building team rapport than clicking through a virtual interface.

Facilitator Intensity: While some games are self-paced, the most impactful MoreSteam simulations (like InBox) typically require a trained facilitator to debrief the "chaos" of the first round.

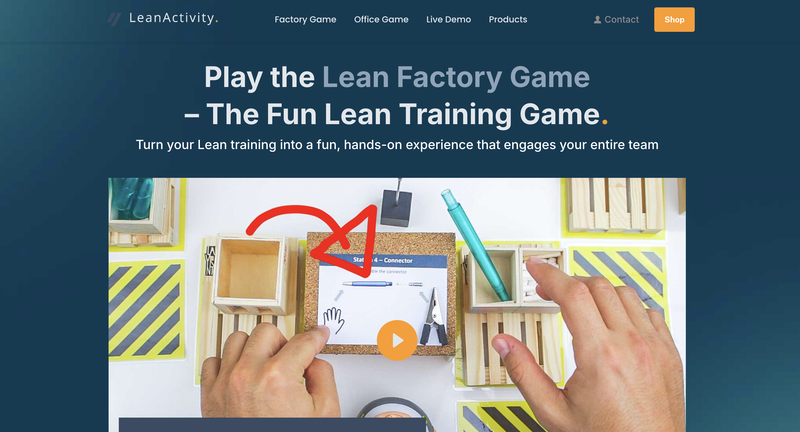

LeanActivity

LeanActivity offers interactive, hands-on simulation games designed to teach Lean Management principles through gamification. Their products are sold as physical kits (often in durable trolley cases) accompanied by digital instructions and training videos. Their flagship product, Lean Factory Game, is designed to simulate a production environment. Participants take on roles (operators, logistics, etc.) in a factory that manufactures pens. The game starts with a chaotic, inefficient process and evolves through 10 rounds of improvements.

Advantages

Training Automation: Their Video Platform acts as a digital co-trainer. It guides the group, explains the tools, and keeps the timing, allowing a team lead or a less-experienced HR person to run a successful 4-hour session with minimal preparation.

Scale and Professionalism: Unlike Lean Lego games, LeanActivity uses custom-designed, 1:10 scale wooden pallets, miniature forklifts, and realistic factory components (pens). This "industrial" feel helps blue-collar workers and executives take the simulation more seriously than they might with children's toys.

Rapid Results: The games are structured to be completed in a tight 4-hour window, whereas many academic or consulting simulations (like the MIT Lego Simulation) can take a full 8-hour day or multiple sessions to complete.

Disadvantages

Higher Initial Cost: Compared to a bag of Legos, LeanActivity requires a significant upfront investment ($3000+ per kit). For a small company doing a one-off training, this may be hard to justify.

Physical Limitations (vs. Digital): Physical kits are capped at 6-12 players per set. If you have 50 people to train, you either need multiple kits or multiple days of training.

Fixed Logic: Because the game is "video-moderated," it follows a set order. Trainers may find harder to propose a different learning path, for example more aligned with the challenges of their own company.

Gemba Academy’s Lean Simulations

Gemba Academy is a global leader in Lean and Six Sigma education, and proposes a massive library of over 2,000 high-quality training videos and professional certifications.

Rather than complex software, Gemba Academy focuses on "low-tech, high-impact" simulations that can be run in a classroom or directly in the workplace. Their most famous example is the Bouncy Ball Game, a high-energy exercise where participants pass balls through a "process" to experience the stark difference between the bottlenecks of Batch Processing and the efficiency of One-Piece Flow.

Advantages

High Energy & Interaction: Physical games break the "death by PowerPoint" fatigue and foster spontaneous communication between team members.

No Technical Barriers: You don't need to worry about internet connections, browser compatibility, or login credentials.

Immediate Visibility: You can see the "pile up" of inventory (Work in Progress) physically growing on a table, which is a powerful visual for Lean beginners.

Disadvantages

Geographic Limitations: Difficult or impossible to run with a remote or distributed workforce.

Manual Data Collection: Participants must manually time processes and count defects, which can lead to human error or "fudging" results.

Setup/Cost of Materials: Requires physical props (balls, stopwatches, kits) and a dedicated physical space.

7-Shapes

7-Shapes offers a unique approach to Lean Management training with a 100% digital, video and game-based simulation. The core of the offering is the 7-Shapes School, a serious game platform that simulates a virtual factory producing drones. Players are placed in a 3D environment where they manage a production line. They must handle customer orders, manage inventory, and deal with bottlenecks in real-time.

Advantages

High Scalability: Unlike physical games that require a trainer for every 10–15 people, 7-Shapes can train thousands of employees simultaneously across different global sites in 14+ languages.

Individual Development: Great for students or professionals who want deep knowledge through multiple courses.

ROI Analytics: Provides a dashboard for managers to track individual progress, quiz scores, and "Lean maturity" in real-time. This data that is nearly impossible to capture accurately in a manual Lego game.

Standardized Certification: Offers a clear path from White Belt to Black Belt with consistent training quality that doesn't vary based on the mood or skill of a live facilitator.

Disadvantages

Reduced Social/Team Dynamics: Multiplayer games force people to negotiate, collaborate and discuss next improvement steps. 7-Shapes is primarily an individual experience, no multi-player format, which may not fully replicate the human aspects of real-world change management.

Tech Learning Curve: Some employees may find navigating a 3D video game environment more intimidating than simply playing with building blocks.

Fixed Scenarios: While 7-Shapes offers customization for enterprise clients, most of the game logic is pre-programmed. It can be hard for trainers to adapt the game progression for their own needs.

Hardware Dependencies: Requires stable internet and modern browsers/computers.

Physical Lean Games (Lego & Paper Planes)

Before the rise of digital platforms, physical simulations were the gold standard for Lean training. The Lego Lean Game and the Paper Plane Lean Game are the two most iconic examples. Both rely on the idea that participants understand Lean better when they are physically moving parts, folding paper, and navigating the "clutter" of a real-world workspace.

In a Lego simulation, teams build complex models (like houses or vehicles) to learn about assembly line balancing and WIP. In the Paper Plane game, teams fold and "flight-test" planes to understand the difference between high-volume output and actual customer value.

Advantages

High Tactile Realism: There is no substitute for the "feel" of a bottleneck. Seeing physical piles of expensive plastic bricks or half-folded planes on a desk makes the cost of inventory feel real and stressful.

The "Flight Test" Value: Unique to the Paper Plane game, the flight test illustrates a vital Lean lesson: a product might look perfect at your station but fail to provide "value" (flight) to the customer.

Near-Zero to Low Cost: Paper planes require only scrap paper, making them the most accessible option for any budget, while Lego kits offer variable complexity for more advanced scenarios.

High Energy & Team Bonding: These games are inherently social and active. They serve as excellent icebreakers and force team members to negotiate and collaborate in close physical proximity.

Disadvantages

Logistical Waste: Physical games require significant setup, cleaning, and "reset" time between rounds. Managing thousands of Lego pieces or re-stocking paper can eat up 20-30% of your total workshop time.

Difficult Data Collection: Because Lead Time and Cycle Time are recorded with manual stopwatches, the data is prone to human error, which can make the debriefing less scientifically accurate.

Scaling & Geographic Limits: You are limited by the number of kits you own and the size of the room. These games are impossible to run remotely.

Lean Game Comparison Table

| Zensimu | MoreStream's InBox | LeanActivity | Gemba Academy | 7-Shapes | Lego & Paper Plane Games | |

|---|---|---|---|---|---|---|

| Format | Fully Digital (SaaS) | Fully Digital (SaaS) | Video-Guided + Physical | Video-Instructions + Physical | 3D Game | Physical |

| Target Environment | Hybrid training workshops and seminars | Hybrid training workshops | Physical training workshops | Distributed learning and certification platform | Distributed learning and certification platform | Physical training workshops |

| Scalability | ✅ High (500+ players) | ⚠️ Moderate (8-15 per run) | ⚠️ Moderate (6-12 per kit) | ⚠️ Moderate (5-10 per team) | ✅ High (Self-paced) | ⚠️ Moderate (4-10 per team) |

| Data Collection | ✅ Automated | ✅ Automated | ❌ Manual | ❌ Manual | ✅ Automated | ❌ Manual |

| Cost | Flexible options (5$-40$ per player) | Starting at 3000$ per session | Around 3000$ per kit | Platform subscription required | 100-300$ per trainee based on courses | 20-100$ of material |

Conclusion

Selecting a Lean game is all about balancing your specific training goals with the logistical needs of your classroom. Whether you prefer the hands-on energy of physical kits or the high-fidelity data of a digital factory, the solutions in this guide offer a great starting point for any instructor looking to bring Continuous Improvement to life.

For instructors who need an immersive, data-driven, and fail-proof experience, we believe Zensimu stands out as the best overall choice. It combines ease of use and extreme scalability with a modern user experience that eliminates the "waste" of manual setup and data collection. This allows you to focus on what matters most: coaching your participants through the transformation from chaos to Kaizen, whether you are hosting a local team of 10 or a global seminar of 500.